Resin domed labels have emerged as a game-changer in the realm of branding and product labeling, offering a seamless blend of aesthetics, durability, and versatility. In this extensive guide, we delve deep into the world of resin domed labels, exploring every facet from their composition and manufacturing intricacies to their wide-ranging applications and myriad benefits. Whether you’re a business owner seeking to elevate your brand’s visibility or a consumer intrigued by personalized products, this guide serves as your compass through the captivating landscape of resin domed labels.

1. What are resin domed labels?

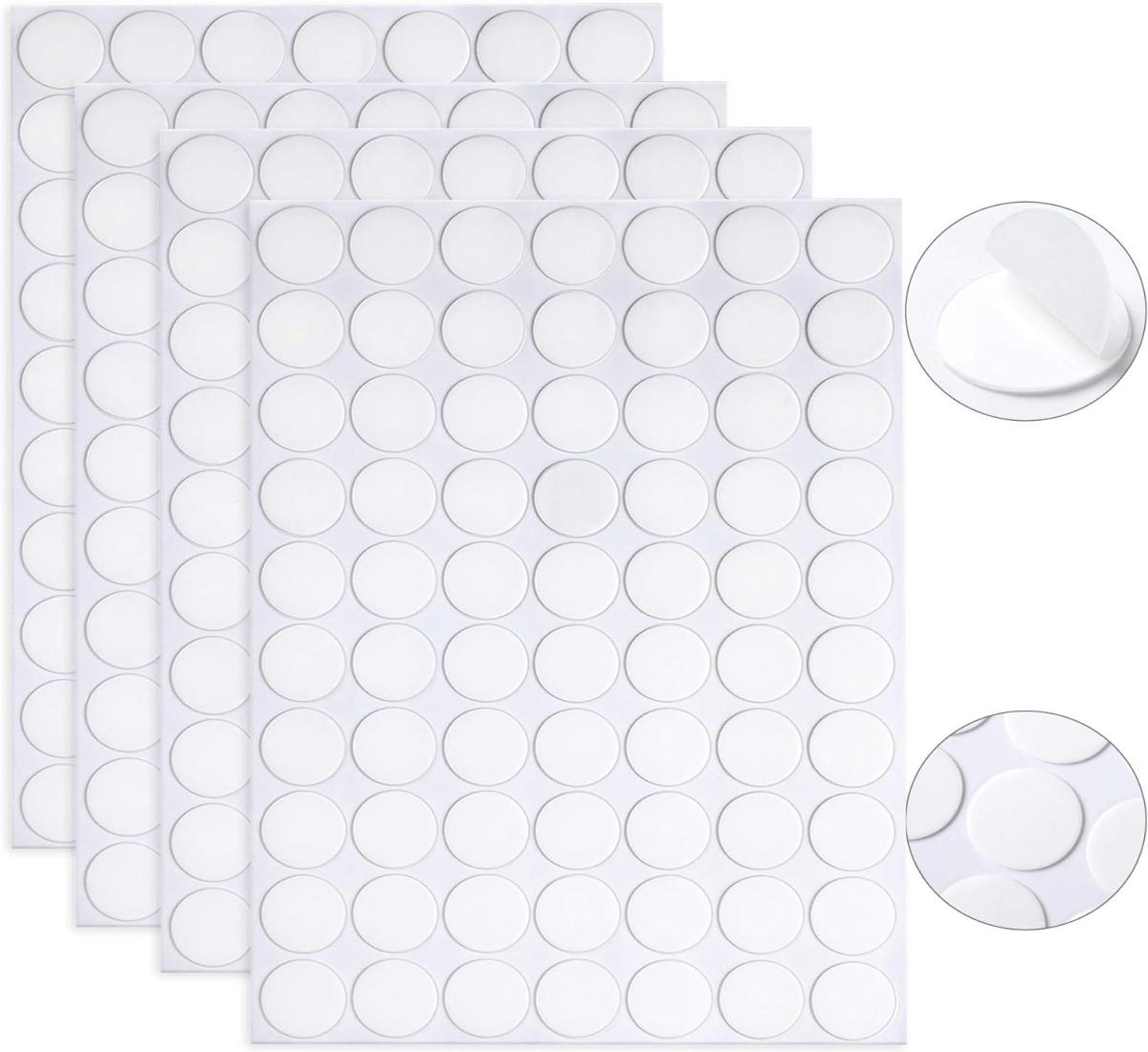

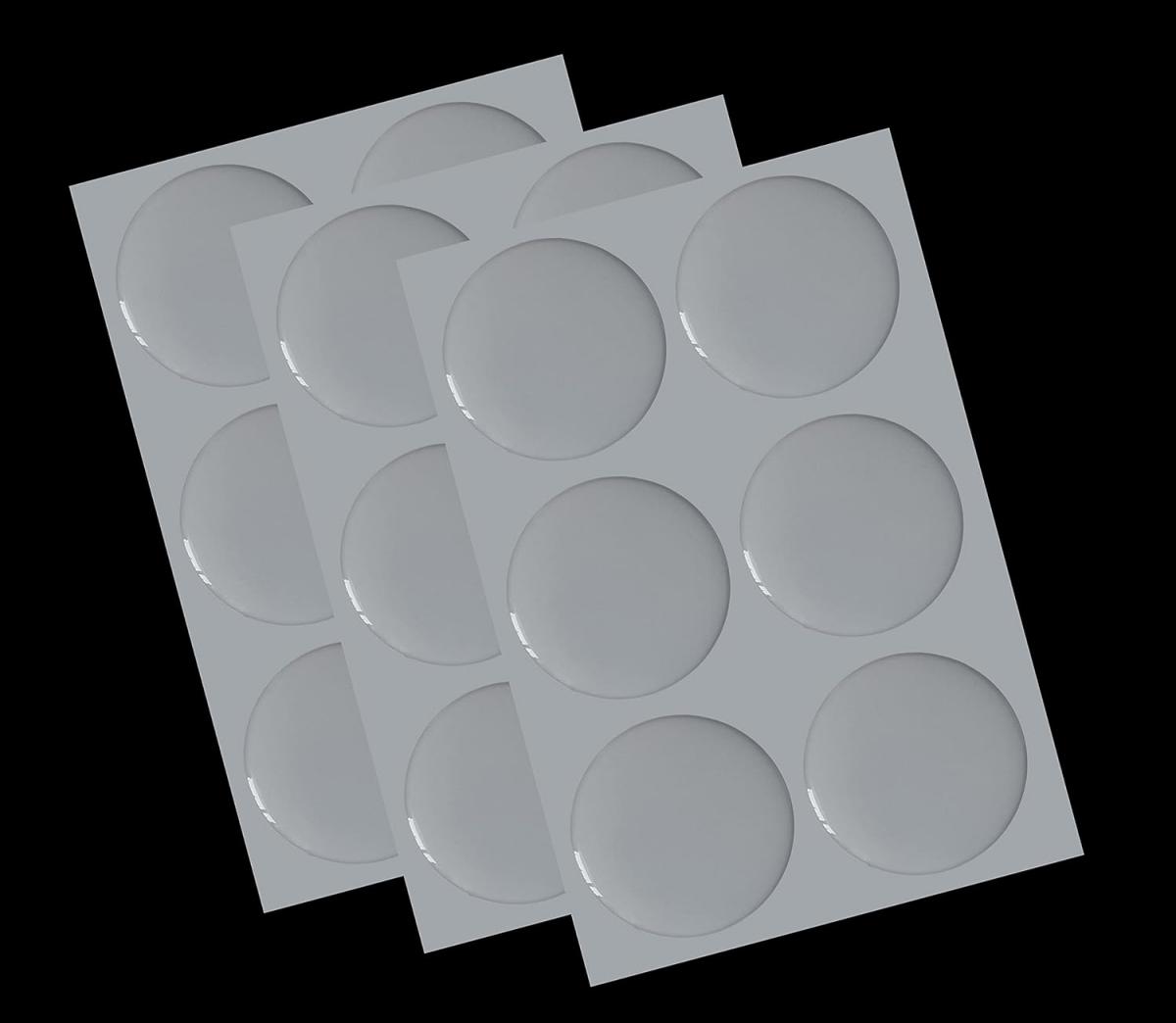

Resin domed labels stand out as labels adorned with a distinctive clear, domed resin coating on their surface. Typically crafted from polyurethane or epoxy resin, this resin layer not only amplifies the visual allure of the label but also confers upon it a plethora of functional advantages. Renowned for their glossy finish, three-dimensional effect, and resilience to various environmental elements, resin domed labels have cemented their status as a sought-after choice for branding, product labeling, and decorative applications.

2. Types of resin domed labels

The realm of resin domed labels encompasses a diverse array of types, distinguished by the type of resin employed and the nuances of the manufacturing process. Here’s a glimpse into some prevalent types of resin domed labels:

1) Polyurethane resin domed labels

Pros: resin domed labels boast a soft texture, exceptional transparency, and resistance to yellowing.

Cons: resin domed labels tend to incur a higher cost and exhibit relatively lower hardness compared to epoxy resin counterparts.

2) Epoxy resin domed labels

Pros: resin domed labels are characterized by high hardness, commendable chemical resistance, and cost-effectiveness.

Cons: resin domed labels have slightly compromised transparency and susceptibility to yellowing over prolonged periods.

3) UV 3D domed labels

Pros: 3D domed labels feature a rapid curing process, superior transparency, and eco-friendly attributes.

Cons: 3D domed labels mandate specialized UV curing equipment, initial cost implications.

3. Advantages of resin domed labels

The allure of resin domed labels lies in the multitude of benefits they offer, making them a preferred choice across diverse applications:

1) Durability

The robust resin coating of resin domed labels bestows exceptional protection against wear and tear, ensuring that the labels retain their visual appeal over extended durations.

2) Aesthetics

The clear, domed resin layer imparts a captivating three-dimensional effect to the labels, elevating their visual charm and augmenting the overall aesthetics of the product.

3) Weather Resistance

resin domed labels exhibit remarkable resistance to UV rays, water, and temperature fluctuations, rendering them suitable for both indoor and outdoor settings.

4) Versatility

These resin-domed labels lend themselves to extensive customization in terms of shape, size, color, and design, offering boundless possibilities for branding and product labeling endeavors.

4. Disadvantages of resin domed labels

While the advantages of resin domed labels are abundant, it’s imperative to acknowledge the accompanying drawbacks:

1) Production cost

The intricate manufacturing process of resin domed labels can translate into elevated production costs vis-a-vis conventional labels.

2) Production time

The curing duration of the resin can prolong the production cycles of resin-domed labels, necessitating patience, and meticulous planning.

3) Environmental concerns

Certain resin materials utilized in resin-domed labels may emit harmful substances during curing, posing environmental challenges. However, UV resin emerges as a more eco-conscious alternative.

5. Applications of resin domed labels

resin domed labels find versatile applications across a spectrum of industries and settings, including but not limited to:

1) Brand logos

Instrumental in crafting eye-catching logos for products and packaging, thereby amplifying brand visibility and recognition.

2) Industrial labels

Deployed equipment, machinery, and control panels to furnish durable and enduring labeling solutions.

3) Promotional products

Integrated into promotional items, gifts, and merchandise to infuse a premium aesthetic and tactile appeal.

4) Automotive industry

A staple choice for car emblems, dashboard labels, and automotive branding owing to their durability and weather-resilient attributes.

6. How to Choose resin domed labels?

When navigating the realm of resin domed labels to select the ideal fit for your unique requisites, consider the following pivotal factors:

1) Usage environment

Opt for a resin type that aligns with the environmental conditions the labels will be subjected to, such as UV resistance for outdoor applications.

2) Cost considerations

Strike a balance between the performance merits of the resin and the overall cost to ensure alignment with your budgetary constraints and operational needs.

3) Brand image

Select resin domed labels that harmonize with your brand’s ethos and messaging, enhancing the overall aesthetic appeal of your products and augmenting brand identity.

4) Environmental impact

For those prioritizing sustainability, UV resin domed labels emerge as a conscientious choice, offering a more eco-friendly solution.

7. Resin domed label FAQs

The following are some common questions about resin domed labels.

1) Are resin domed labels Waterproof?

Yes, resin domed labels exhibit waterproof properties, rendering them apt for deployment in damp or outdoor environments.

2) What is the Lifespan of resin domed labels?

resin domed labels boast a lifespan ranging from 5 to 10 years, contingent upon the quality of the resin and the maintenance regimen adhered to.

3) Can resin domed labels be Applied to Curved Surfaces?

Indeed, resin domed labels possess the flexibility to conform to curved surfaces, provided the surface is pristine and devoid of debris for optimal adhesion.

4) Do resin domed labels Yellow Over Time?

Polyurethane resin domed labels showcase resistance to yellowing, whereas epoxy resin labels may exhibit slight yellowing with prolonged exposure to sunlight.

5) How Long Does it Take to Produce resin domed labels?

The production timeline for resin domed labels can fluctuate based on the curing process and intricacy of the design, typically spanning from 3 to 7 days.

8. Conclusion

Resin domed labels emerge as a quintessential asset in the realm of labeling and branding, offering a harmonious amalgamation of visual allure, durability, and customization options. By delving into the nuances of resin domed labels encompassing types, advantages, disadvantages, applications, and selection criteria, you equip yourself with the knowledge to make informed decisions that resonate with your specific needs and preferences.

Whether your aim is to elevate your brand’s image or infuse a personalized touch into your products, resin domed labels stand poised as a valuable ally in your branding and labeling endeavors. We trust that this comprehensive guide has equipped you with invaluable insights and information to navigate the enchanting universe of resin domed labels with confidence and clarity, empowering you to make astute choices that resonate with your branding aspirations and product labeling goals.